Features

1. It is installed under the ores bin, feeding size is not bigger than 50mm. It is suitable for the dry material which is not easy to lump. It is not suitable for transporting powder material.

2. the machine can also be used as a locking device when it is not working.

Working principle

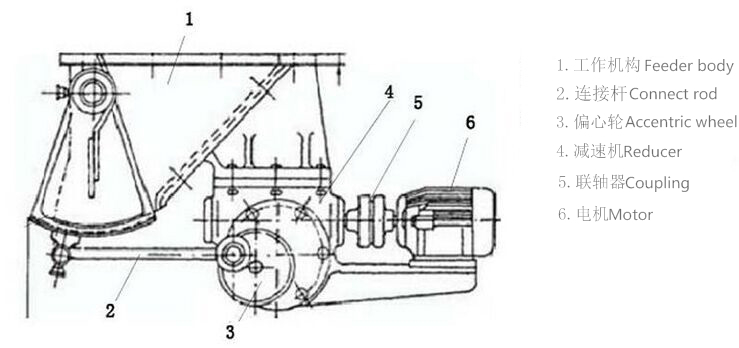

This machine adopts eccentric wheel mechanism, the jaw plate do reciprocating movement.The material will be evenly distributed. The eccentric wheel is driven by a motor through a turbine speed reducer, and then the circular motion is changed into reciprocating motion via the connecting rod, and the reciprocating motion of the jaw plate is driven. When the jaw plate clockwise swing on it making the accumulation of material due to friction and driven with movement, to fill the body outwards by the space formed from the storage hopper in the pouring down part of the new material, when the jaw does anti clockwise movement, because the barrier material within the material cannot follow the jaw plate into the body inside, so it is in its under the push by the feeding tube or conveyor feeding funnel,all in all short periodic oscillation can make the jaw plate continuous material feeding.

This machine adopts eccentric wheel mechanism, the jaw plate do reciprocating movement.The material will be evenly distributed. The eccentric wheel is driven by a motor through a turbine speed reducer, and then the circular motion is changed into reciprocating motion via the connecting rod, and the reciprocating motion of the jaw plate is driven. When the jaw plate clockwise swing on it making the accumulation of material due to friction and driven with movement, to fill the body outwards by the space formed from the storage hopper in the pouring down part of the new material, when the jaw does anti clockwise movement, because the barrier material within the material cannot follow the jaw plate into the body inside, so it is in its under the push by the feeding tube or conveyor feeding funnel,all in all short periodic oscillation can make the jaw plate continuous material feeding.

Parameters

Model | Inlet mm | Outlet mm | Max feeding size mm | Capacity t/h | Motor | Weight kg | |

Model | Power kw | ||||||

250X250 | 250X250 | 250*30-115 | 25 | 4.5 | Y801-4 | 0.55 | 130 |

300X300 | 300X300 | 300*30-125 | 30 | 6.5 | Y802-4 | 0.75 | 272 |

400X400 | 400X400 | 400*50-130 | 35 | 12 | Y90S-4 | 1.1 | 558 |

600X600 | 600X600 | 600*50-150 | 50 | 25 | Y90L-4 | 1.5 | 613 |

简体中文

简体中文 English

English Español

Español русский

русский