Features

1. It can be put on the ground and can be hoisted on the unloading port of the mine.

2. It is convenient to change and control the flow at any time.

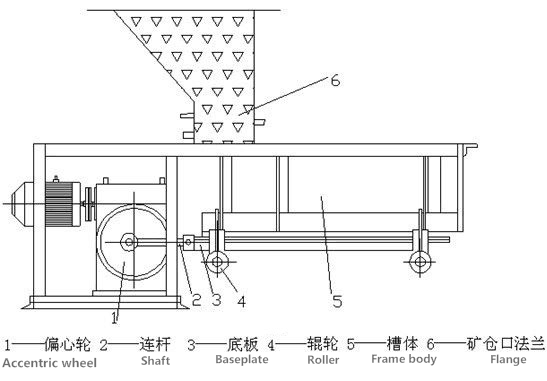

3. The trough floor is reciprocated, and the stroke can be adjusted properly by the eccentric wheel of the driving device.

4. The slot width of the slot feeder is about 3 times the maximum granularity of the feed.

Working principle

Usually installed under the ore bin, ores go into the bottom of the groove on the bottom of the bushing, bushing is arranged in the roller, and the eccentric mechanism makes the bushing and double shaft of the speed reducer connected, and then with the motor coupling. When the utility model is used, the motor drives the speed reducer through the coupling, and the device is driven by the eccentric disk to reciprocate linearly with the leaking disk between the bottom of the groove frame and the roller.

Usually installed under the ore bin, ores go into the bottom of the groove on the bottom of the bushing, bushing is arranged in the roller, and the eccentric mechanism makes the bushing and double shaft of the speed reducer connected, and then with the motor coupling. When the utility model is used, the motor drives the speed reducer through the coupling, and the device is driven by the eccentric disk to reciprocate linearly with the leaking disk between the bottom of the groove frame and the roller.

Parameters

Model | Oulet mm | Max feeding size mm | Capacity m3/h | Motor | Weight kg | |

Model | Power kw | |||||

300X300 | 300X300 | 50 | 10-20 | Y90L-4 | 1.5 | 265 |

400X400 | 400X400 | 100 | 10-30 | Y112-6 | 2.2 | 535 |

600X500 | 600X500 | 200 | 10.5-25.5 | Y112M-6 | 4 | 1054 |

700X500 | 700X500 | 250 | 10-60 | Y112M-6 | 4 | 1100 |

1000X1900 | 1000X1900 | 300 | 300 | Y160M-4 | 7.5 | 2691 |

1240X980 | 1240X980 | 350 | 40-90 | Y160M-6 | 7.5 | 1710 |

1240X1100 | 1240X1100 | 400 | 61-150 | Y160M-4 | 11 | 1850 |

1400X2000 | 1400X2000 | 300 | 50-101 | JZT52-6 | 7.5 | 3472 |

2400X1200 | 2400X1200 | 350 | 120-150 | YCT225-4B | 15 | 3183 |

2300X1400 | 2300X1400 | 300 | 250-500 | Y180M-4 | 18.5 | 6895 |

简体中文

简体中文 English

English Español

Español русский

русский