Features

1.It is advanced developed based on the latest technology introduced from Germany, which not only improves productivity and efficiency, but also expands the scope of application.

2.Good crushing performance in crushing, fine crushing and superfine crushing of various materials from limestone to basalt, from stone production to a variety of ores.

3.High efficiency.Both ends of the hydraulic cone crusher have spindle support, so it’s able to withstand greater crushing force and greater stroke. If added with special crushing cavity adapting lamination principle, the machine has higher efficiency.

4.Huge capacity.It has a perfect design combination of crushing stroke, crushing speed and crushing cavity shape, which makes the machine have 35%~60% higher output than the old spring cone crusher in the condition of same fixed cone diameter.

5.High quality of finished products.The hydraulic cone crusher uses special crushing cavity, as well as the principle of laminated design, so that the cube proportions of finished product is significantly increased, with less needle-shaped stones and more even particle levels.

Working principle

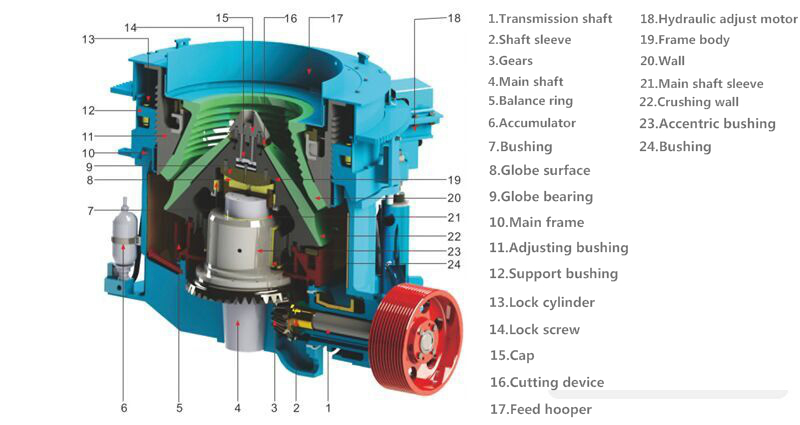

Hydraulic cone crusher consists of frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, motor drives eccentric shaft shell to rotate through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

Hydraulic cone crusher consists of frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, motor drives eccentric shaft shell to rotate through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

Parameters

Model | Type of broken cavity | Discharge outlet mm | Feed inlet mm | Capacity t/h | Power kw | Weight t |

HPT200 | Fine | ≥13 | 95 | 120-200 | 160 | 13.5 |

Middle | ≥16 | 120 | 140-220 | |||

Rough | ≥19 | 190 | 150-250 | |||

HPT300 | Fine | ≥13 | 105 | 110-260 | 250 | 18 |

Middle | ≥16 | 150 | 175-320 | |||

Rough | ≥20 | 210 | 190-380 | |||

HPT400 | Fine | ≥14 | 110 | 185-345 | 315 | 26 |

Middle | ≥20 | 196 | 255-430 | |||

Rough | ≥25 | 251 | 295-560 | |||

HPT500 | Fine | ≥16 | 135 | 280-455 | 400 | 37 |

Middle | ≥22 | 210 | 345-605 | |||

Rough | ≥30 | 290 | 405-790 |

简体中文

简体中文 English

English Español

Español русский

русский