Features

1.Cubic-shaped end products.

2.Adjustable end products sizes, simple crushing process.

3. The board hammer is made of high chrome and abrasion-resistant with powerful impacting force.

4. Easy to maintenance and cost-saving.

5. Sound construction and high efficiency.

Working principle

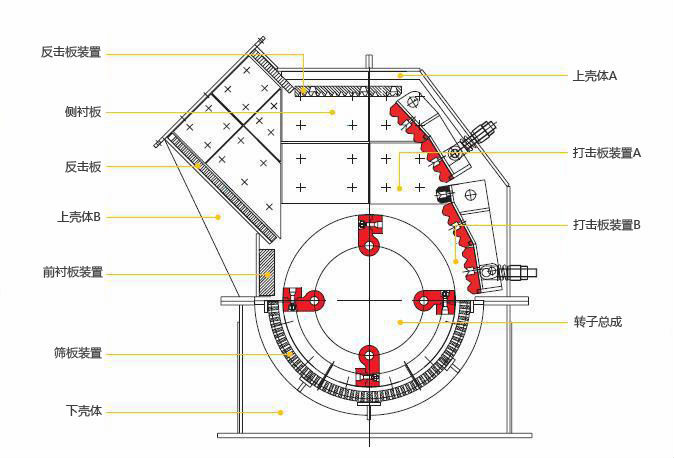

The materials are crushed via impact energy produced in the impact crusher. When the materials enter the zone of the board hammer, they are flung into the impact equipments via the high-speed impact of the board hammer. These materials will be re-crushed after rebounding into the scale board. The large materials are crushed into small pieces until it becomes the specified granularities. The end products come out from the base of the impact crusher.

The materials are crushed via impact energy produced in the impact crusher. When the materials enter the zone of the board hammer, they are flung into the impact equipments via the high-speed impact of the board hammer. These materials will be re-crushed after rebounding into the scale board. The large materials are crushed into small pieces until it becomes the specified granularities. The end products come out from the base of the impact crusher.

Parameters

Model | Max feeding size mm | Max discharge size mm | Capacity m3/h | Power kw | Weight t | Dimension mm |

PC400×300 | 200 | 25 | 5-10 | 11 | 0.8 | 900×670×860 |

PC600×400 | 250 | 30 | 10-22 | 22 | 2.26 | 1200×1050×1200 |

PC800×600 | 250 | 35 | 18-40 | 55 | 4.8 | 1310×1180×1310 |

PC1000×800 | 350 | 35 | 25-50 | 75 | 5.9 | 1600×1390×1575 |

PC1000×1000 | 350 | 35 | 30-55 | 90 | 8 | 1800×1590×1775 |

PC1200×1200 | 350 | 35 | 50-80 | 132-160 | 19.2 | 2060×1600×1890 |

PC1400×1400 | 350 | 35 | 50-100 | 280 | 32 | 2365×1870×2220 |

PC1600×1600 | 350 | 35 | 100-150 | 480 | 37.5 | 3050×2850×2800 |

简体中文

简体中文 English

English Español

Español русский

русский