Features

1. The curvature of the cone end cap of the rod mill is small, and the steel bar can move in regular motion in the mill.

2. The hollow shaft of the mine is large in diameter and is easy to repair. At the same time, the slurry surface can be reduced and the ore is discharged quickly.

3. The grinded size is uniform, few overgrinded.

4. The hollow shaft is cast steel, the inner lining can be dismantled, the rotary big gear is machined by the casting hobbing, and the body has the wear-resistant lining plate in the barrel, and it has good wear resistance.

5. The machine runs smoothly, and the work is reliable.

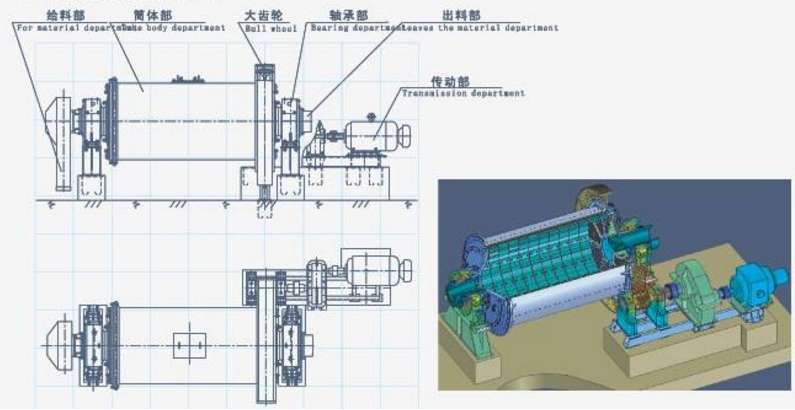

Working principle

The main component of wet rod mill is a cylinder which is revolved by motor. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill.

The main component of wet rod mill is a cylinder which is revolved by motor. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill.

Parameters

Model | Cylinder | Motor | Dimension mm | Volume m3 | Max rods loading t | Weight kg | |||||

Diameter mm | Length mm | Revolution rpm | Model | Power kw | L | W | H | ||||

MBY 0918 | 900 | 1800 | 22 | Y225M-8 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

MBY 0924 | 900 | 2400 | 30 | Y250M-8 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 |

MBY 1224 | 1200 | 2400 | 45 | Y280M-8 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 |

MBY 1530 | 1500 | 3000 | 95 | JR125-8 | 725 | 7935 | 3185 | 2280 | 0.4~4.9 | 5 | 19990 |

MBYg 1530 | 1500 | 3000 | 80 | JR117-8 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 |

MBYg 2130 | 2100 | 3000 | 180 | JR136-8 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 |

MBYg 2136 | 2100 | 3600 | 210 | JR137-8 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 |

MBYg 2430 | 2400 | 3000 | 280 | JR138-8 | 735 | 9005 | 4836 | 3490 | 43~61 | 11.5 | 55795 |

MBYg 2732 | 2700 | 3200 | 320 | JR157-8 | 750 | 10509 | 5000 | 3620 | 43~61 | 15.7 | 83110 |

MBYg 2736 | 2700 | 3600 | 380 | JR158-8 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 |

MBY 2740 | 2700 | 4000 | 400 | TDMK400-32 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

MBY 3040 | 3000 | 4000 | 570 | JR1510-8 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

MBY 3245 | 3200 | 4500 | 800 | TDMK800-36 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

MBY 3645 | 3600 | 4500 | 1250 | TDMK1250-40 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

MBY 3654 | 3600 | 5400 | 1600 | TDMK1600-40 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |

简体中文

简体中文 English

English Español

Español русский

русский