Features

1. The automatic lifting device for the return sand is added to the end of the sand return, and the configuration of the head of the ball mill is cancelled.

2. each ton of ore can save 1 to 1.5 degrees.

3. avoid the frequent overhaul of the big spoon head.

4. slow down the uneven impact on the large and small gear of the ball mill.

5. with the ball mill drum feeder supporting increased sand-scraping device, so that the flow of mortar from the side of the mill drum feeder.

6. models grading machine uses rolling instead of the original bearing, reducing friction and avoid frequent replacement of the bearing repair, using ZQ reducer, reducing installation and maintenance space.

7. Improved lubrication components, large-sized product with dry pumps, lubrication and reliable.

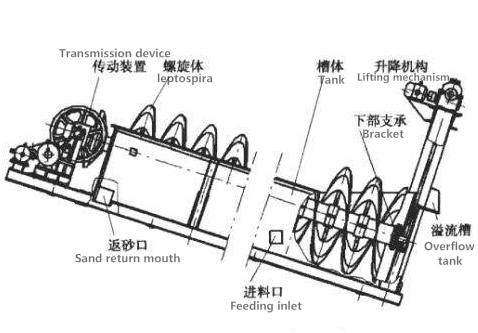

Working principle

The tank is slantly installed. The inclination angle depends on equipment configuration in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the tank. The finely grained slurry enters the tank from the feeding inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank’s inclination angle and the height of overflow edge. The spirals rotate at low speed to play stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. Classifiers normally form closed loop operation together with mill.

The tank is slantly installed. The inclination angle depends on equipment configuration in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the tank. The finely grained slurry enters the tank from the feeding inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank’s inclination angle and the height of overflow edge. The spirals rotate at low speed to play stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. Classifiers normally form closed loop operation together with mill.

Parameters

Type | Model | Spiral diameter | Spiral revolution | tank | Capacity t/d | transmission power | Lifting power | |||

mm | rpm | L mm | W mm | Inclination angle | Overflow | Return | kw | kw | ||

High weir single spiral | FG-5 | 500 | 9.2 | 3900 | 560 | 10.5°-14° | 21-75 | 145-260 | 3 | 1.1 |

FG-7 | 750 | 7.8 | 5367 | 830 | 10.5°-14° | 65-154 | 255-564 | 3 | 3 | |

FG-10 | 1000 | 7 | 6500 | 1110 | 10.5°-14° | 85 | 473-1026 | 5.5 | 5.5 | |

FG-12 | 1200 | 5,6,7 | 6500 | 1372 | 10.5°-14° | 150 | 1145-1600 | 5.5 | 5.5 | |

FG-15 | 1500 | 2.5,4,6 | 8265 | 1664 | 14°-18.5° | 235 | 1140-2740 | 7.5 | 7.5 | |

FG-20 | 2000 | 5.4 | 8400 | 2396 | 14.5°-18.5° | 400 | 5940 | 15 | 2.2 | |

FG-24 | 2400 | 3.6,5.4,6.3 | 9160 | 2600 | 14°-18.5° | 580 | 6800 | 11/15 | 2.2 | |

FG-30 | 3000 | 3.17 | 12500 | 3200 | 14°-18.5° | 890 | 11650 | 22 | 4 | |

High weir double spiral | 2FG-12 | 1200 | 5,6,7 | 6500 | 2620 | 14°-10.5° | 300 | 2290-3200 | 5.5X2 | 2.2X2 |

2FG-15 | 1500 | 2.5,4,6 | 8265 | 3200 | 14°-18.5° | 460 | 2240-5360 | 7.5X2 | 2.2X2 | |

2FG-20 | 2000 | 5.4 | 8400 | 4296 | 14.5°-18.5° | 800 | 11880 | 15X2 | 2.2X2 | |

2FG-24 | 2400 | 3.6,5.4,6.3 | 9160 | 5040 | 14°-18.5° | 1160 | 13600 | 11X2/15X2 | 2.2X2 | |

2FG-30 | 3000 | 3.17 | 12500 | 6300 | 14°-18.5° | 1785 | 23300 | 22X2 | 4X2 | |

简体中文

简体中文 English

English Español

Español русский

русский