Features

1. the suction volume is large and the energy consumption is small.

2. self - suction air, self - sucking pulp capacity, horizontal configuration, no need for foam pump.

3. the speed around the impeller circle is low, and the wear life of the worn parts is long. The gap between the impeller and the cover plate is large. The gap between the impeller and the cover increases due to wear, and the clearance has little influence on the intake volume.

4. the slurry in the trough is circulate up and down in a fixed flow way, which is beneficial to the suspension of the coarse grain minerals.

Working principle

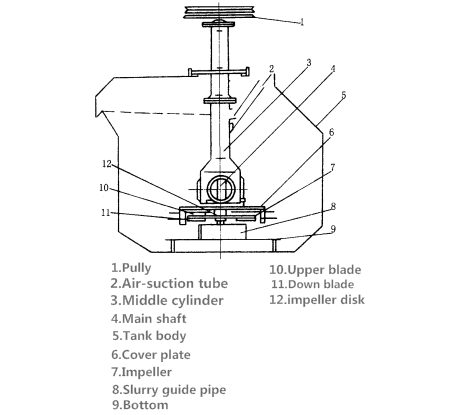

When the motor drives the impeller to revolve, the centrifugal force and negative pressure are generated. On one hand, ample air is absorbed and mixed with mine slurry. On the other hand, the mixed slurry is mingled with additive. meanwhile the foams are thinning, the mineral is bounded with foams, and floats go up to the surface of mine slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, thus the useful foams are scraped with squeegee.

When the motor drives the impeller to revolve, the centrifugal force and negative pressure are generated. On one hand, ample air is absorbed and mixed with mine slurry. On the other hand, the mixed slurry is mingled with additive. meanwhile the foams are thinning, the mineral is bounded with foams, and floats go up to the surface of mine slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, thus the useful foams are scraped with squeegee.

Parameters

Model | Volume m3 | Capacity m3/min | Impeller diameter mm | Impeller revolution rpm | Mixing motor power kw | Scraping motor power kw | Weight kg |

SF-0.37 | 0.37 | 0.2~0.4 | 300 | 352~442 | 1.5 | 0.55 | 468 |

SF-0.7 | 0.7 | 0.3~1.0 | 350 | 336~384 | 3 | 1.1 | 629 |

SF-1.2 | 1.2 | 0.6~1.6 | 450 | 312 | 5.5 | 1.1 | 1373 |

SF-2 | 2 | 1.5 ~3 | 550 | 280 | 11 | 1.5 | 1879 |

SF-2.8 | 2.8 | 1.5~3.5 | 550 | 280 | 11 | 1.5 | 1902 |

SF-4 | 4 | 2.0 ~4 | 650 | 235 | 15 | 1.5 | 2582 |

SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 | 3540 |

SF-8 | 8 | 4.0 ~8 | 760 | 191 | 30 | 2.2 | 4129 |

SF-16 | 16 | 5.0 ~16 | 850 | 169~193 | 45 | 1.5 | 7415 |

SF-20 | 20 | 10 ~12 | 850 | 169~193 | 45 | 1.5 | 9828 |

简体中文

简体中文 English

English Español

Español русский

русский