Features

1. Using the rolling principle, the friction coefficient is small, the wear is light, and the sieve hole is not easy to clog.

2. The roller bearing adopts the whole shaft structure, which runs smoothly, does not vibrate, and the noise is low.

3. The inner cylinder mesh fittings are designed with split body. The structure is simple and the replacement is quick and convenient.

4. the roller body uses the effective full seal structure, does not lift the dust, does not pollute.

5. the operation is safe and reliable, the speed reduction drive is adopted, the transmission efficiency is high, the power distribution is small, the energy consumption is low, and the energy saving effect is obvious.

6. according to customer requirements, different screen mesh material, sieve size, high screening efficiency, long service life, low maintenance cost.

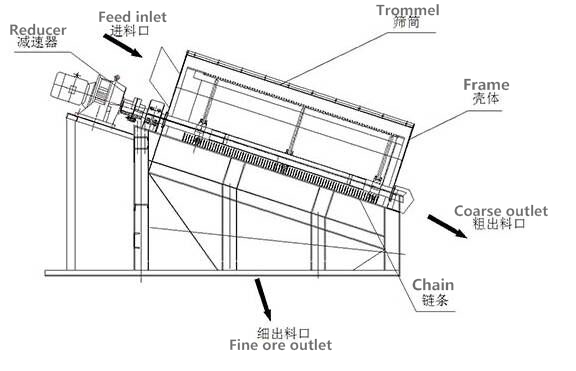

Working principle

The roller device is tilted on the rack. The motor is connected by a coupling through a coupling through a reducer and a roller device, and the driving roller device rotates around its axis. When the material enters the cylinder device, due to tilting and rotating drum device, so that the screen material turnover and rolling, the fine materials (sieve products) is discharged through the discharge port at the bottom of the rear end of the drum, larger materials (sieve products) is discharged through the discharge port of the cylinder tail。

The roller device is tilted on the rack. The motor is connected by a coupling through a coupling through a reducer and a roller device, and the driving roller device rotates around its axis. When the material enters the cylinder device, due to tilting and rotating drum device, so that the screen material turnover and rolling, the fine materials (sieve products) is discharged through the discharge port at the bottom of the rear end of the drum, larger materials (sieve products) is discharged through the discharge port of the cylinder tail。

Parameters

Model | Capacity tph | Power kw | Trommel diameter mm | Trommel length mm | Feeding size mm | Fine outlet size mm | Dimension mm |

GTS1015 | 50 | 3 | 1000 | 1500 | ≤300 | 0~100 | 2600×1400×1700 |

GTS1020 | 100 | 4 | 1000 | 2000 | 3390×1400×2140 | ||

GTS1225 | 160 | 5.5 | 1200 | 2500 | 4146×1600×2680 | ||

GTS1530 | 250 | 7.5 | 1500 | 3000 | 4460×1900×2820 | ||

GTS1545 | 350 | 11 | 1500 | 4500 | ≤400 | 5960×1900×3080 | |

GTS1848 | 450 | 15 | 1800 | 4800 | 6500×2350×4000 | ||

GTS2055 | 600 | 22 | 2000 | 5500 | 7500×2550×4800 | ||

GTS2265 | 800 | 30 | 2200 | 6500 | 8500×2750×5000 |

简体中文

简体中文 English

English Español

Español русский

русский